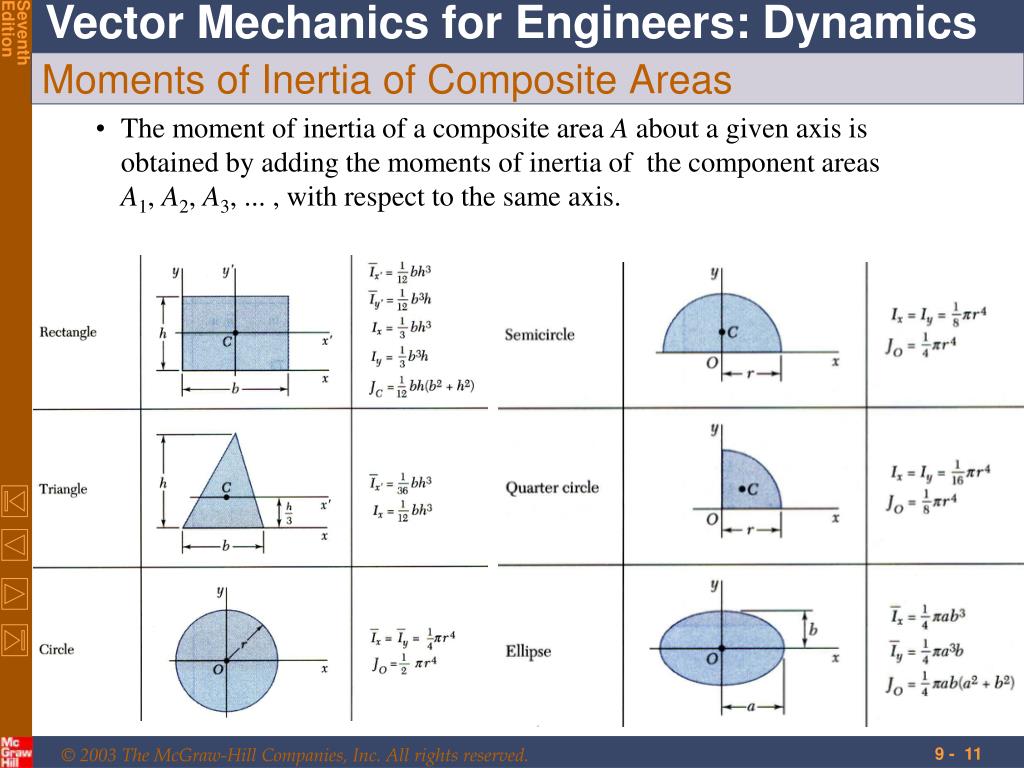

If you plot "I" as a function of position along the central axis, then you have used numerical methods in Creo to do the Calculus. First moment of area is commonly used to determine the centroid of an area. The first moment of area of a shape, about a certain axis, equals the sum over all the infinitesimal parts of the shape of the area of that part times its distance from the axis ad. I y². It is a measure of the spatial distribution of a shape in relation to an axis. The only domain of interest in this case would be where the bias cut is made on the tube as "I" will decrease from the constant value of the tube to zero at the point. The area moment of inertia around xx is calculated using distance to the arbitrary axis xx, given the coordinate along with yy. You could have Creo calculate "I" at discrete steps and plot the value as a function of the distance along the central axis of the tube. The area moment of inertia (also referred to as second moment of area) is a geometrical property of a shape describing the distribution of points around an. You can plot these values as well in BMX. With BMX there is a special type of datum point (a field point) that will support automating finding the min/max value within a specified domain automatically. Using the Creo BMX extension, you can take the cross section at a specific point. It only changes at the bias cut forming the point of the needle.Ĭreo can in theory measure "I" at any cross section with a closed area. I am assuming that you are interested in t he moment of inertia of circular tube with respect to any axis passing through its centroid which is a constant value if the tube wall is a constant. Would the value of I (Kgm^2) with respect to the neutral axis of bending with an assumed loading condition give you what you need? To extrapolate to 3D you would use the mass moment of inertia. Area Moment Of Inertia also known as the Second Moment of Area, is a geometrical property of an area which measures how its points are distributed about an. Do you need the resistance to bending of the tube with a bias cut on the end? The SI units for moment of inertia are Kg m^2 so it is a 2D calculation. It is not clear exactly what you are trying to do. It seems like Creo has lots of capabilities to find the mass properties of different parts, but since I need the area moment of inertia the mass properties are not required and instead geometry is my biggest concern. Please let me know if I can clarify my problem in any way. I thought Creo may have some functionality to do this within the program.

I believe this process would require me to integrate by hand, as well as utilize the parallel axis theorem to connect the conical end of the needle to the cylindrical shaft. I have attached a picture of what the needle end looks like below. I was mostly wondering if Creo is able to find the second area moment over the varying geometry of the conical tip, or if it is only able to find one cross section at a time.

I am trying to calculate the second area moment for a common vascular needle, which has a cylindrical shaft and a conical tip.

Hello! I was wondering about Creo’s capability to measure the Second Area Moment of Inertia (I).

0 kommentar(er)

0 kommentar(er)